Cloud Collaboration

for Industrial Equipment

Manufacturing

Connect industrial electronics design

and manufacturing

and manufacturing

Unite Industrial Electronics Teams with

Secure Cloud-Based Collaboration

Industrial Electronics Challenges

How Altium 365 Helps

How Altium 365 Helps

Mechanical and electrical teams waste time with manual file transfers and version conflicts

- Keep ECAD and MCAD software synchronized with automatic data exchange

Component availability and supply chain disruptions threaten production schedules

- Access comprehensive component data, obsolescence alerts, and lifecycle statuses

Prototyping and manufacturing handoff is slow and error-prone

- Share design data early and perform manufacturability checks to catch issues early

Sensitive design IP is vulnerable when sharing files with external partners

- Control access with granular permissions and encrypted cloud storage

Companies must maintain legacy design data for products with long lifecycles

- Track all design revisions and releases with built-in version control

Accelerate Industrial

Equipment Manufacturing

Equipment Manufacturing

Cut Design and Development Time

Altium 365 is a unified cloud platform that supports collaboration among your electrical and mechanical teams. By bringing together each engineering discipline in a single platform, teams can accelerate time-to-market. Real-time collaboration and integrated workflows save over 159 hours of designer time each year and reduce electronics design costs by $373,800 over three years.

Manage Updates to Legacy Data

Industrial systems can have long lifecycles requiring frequent updates as part of maintenance and obsolescence management. Altium 365’s Git-based version control system tracks all design updates over the entire lifetime of a product. Gain complete traceability for each design in a single cloud platform.

Reduce Component Sourcing Delays

Stay ahead of supply chain disruptions with real-time data on component availability and lifecycle status. Industrial electronics designers have the information they need to make informed decisions during the design phase, helping teams avoid obsolete or hard-to-source parts. Proactive supply chain management ensures a more resilient supply chain and prevents costly production delays.

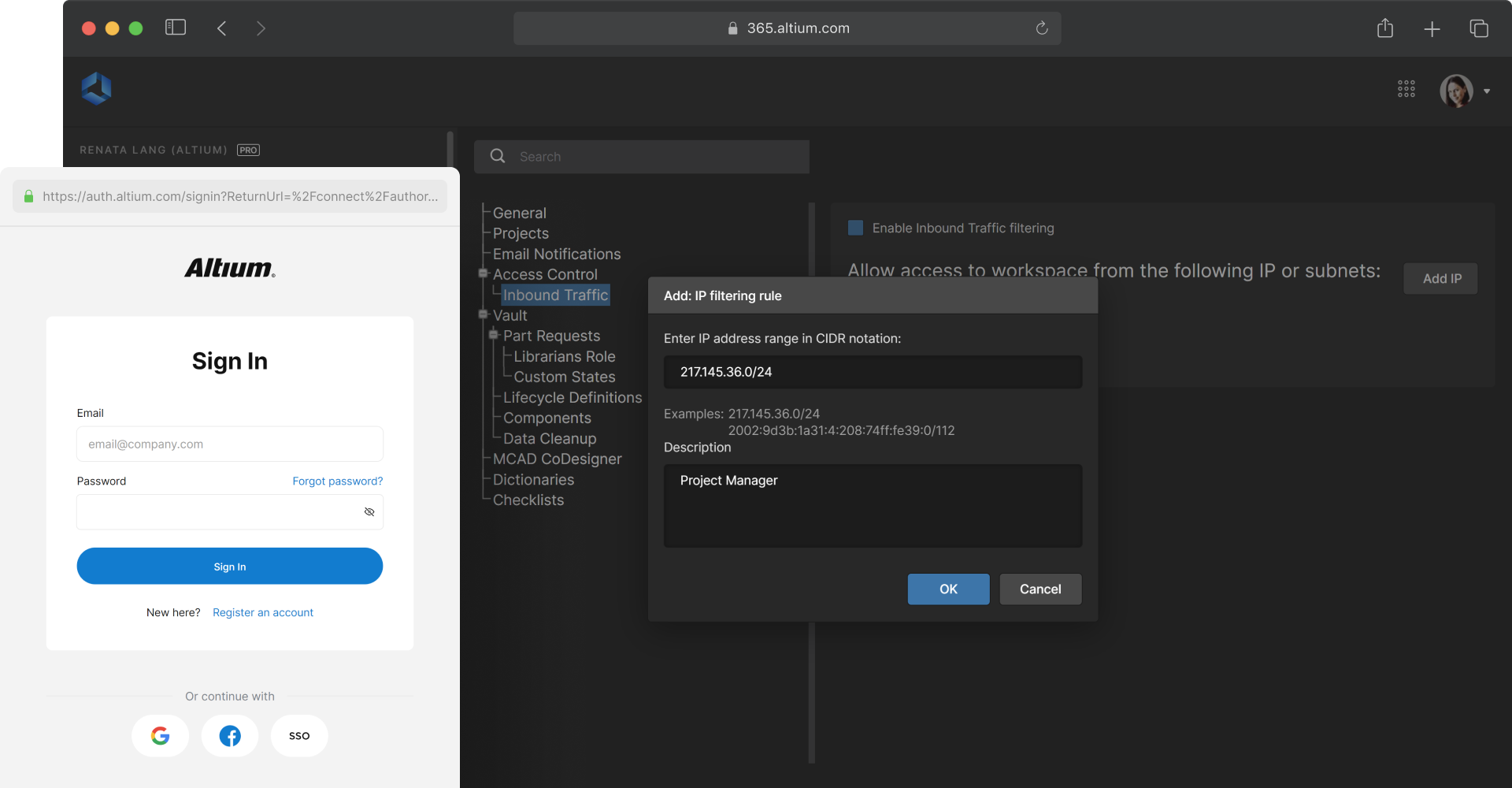

Improve Data Security

Protect your sensitive design data with enterprise-grade encryption, role-based access controls, and IP whitelisting. Advanced access controls allow you to manage who can view and edit your designs. Your teams can share design data securely with external partners and manufacturers while keeping intellectual property fully protected.

Altium 365 Connects

Your Entire Industrial

Electronics Development Team

Altium 365 Connects

Your Entire Industrial

Electronics Development Team

Engineering Manager

Drive efficient design processes for custom-engineered systems from prototype to high-volume manufacturing. Coordinate design changes across the entire team while keeping mechanical, electrical, and embedded engineering teams aligned. Ensure that the final product meets every functional requirement.

Cross-Functional

Team Collaboration

Efficient

Design Coordination

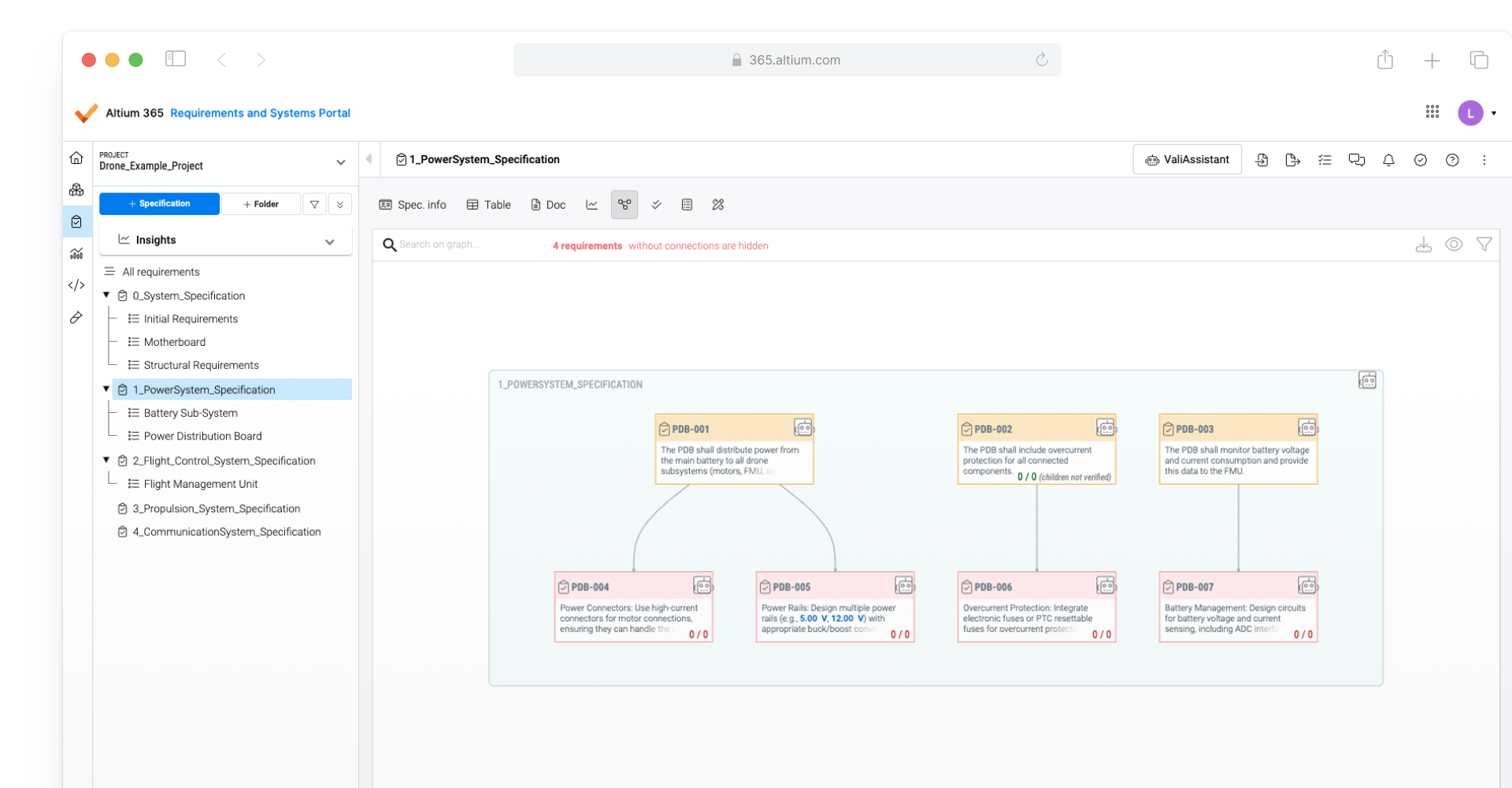

System Architect

Define and validate requirements while maintaining full traceability throughout the product lifecycle. Track design implementations and capture approvals in a centralized requirements management system that links specifications directly to design elements.

Enhanced Traceability

& Collaboration

Simplified

Compliance

Electrical Engineer

Design electrical systems for industrial machinery that meet ISO and IEC standards. Ensure safety, manufacturability, and compliance with specifications and requirements. Collaborate seamlessly with mechanical and software teams using intuitive tools to troubleshoot and efficiently refine designs.

Streamlined

Design Process

Improved

Design Accuracy

Procurement

Access real-time component data, mitigate supply chain risks, and ensure cost-effective sourcing. Streamline decisions with up-to-date insights on component availability while aligning with sustainability and industry standards.

Real-Time

Component Insights

Sustainable &

Compliant Sourcing

IT Security Manager

Safeguard sensitive design data with granular access controls and role-based permissions while ensuring that internal and external teams can securely collaborate. Proactively protect intellectual property with robust monitoring and advanced data security.

Secure

Collaboration

Granular

Access Control

How Altium 365 Streamlines Industrial Equipment Manufacturing

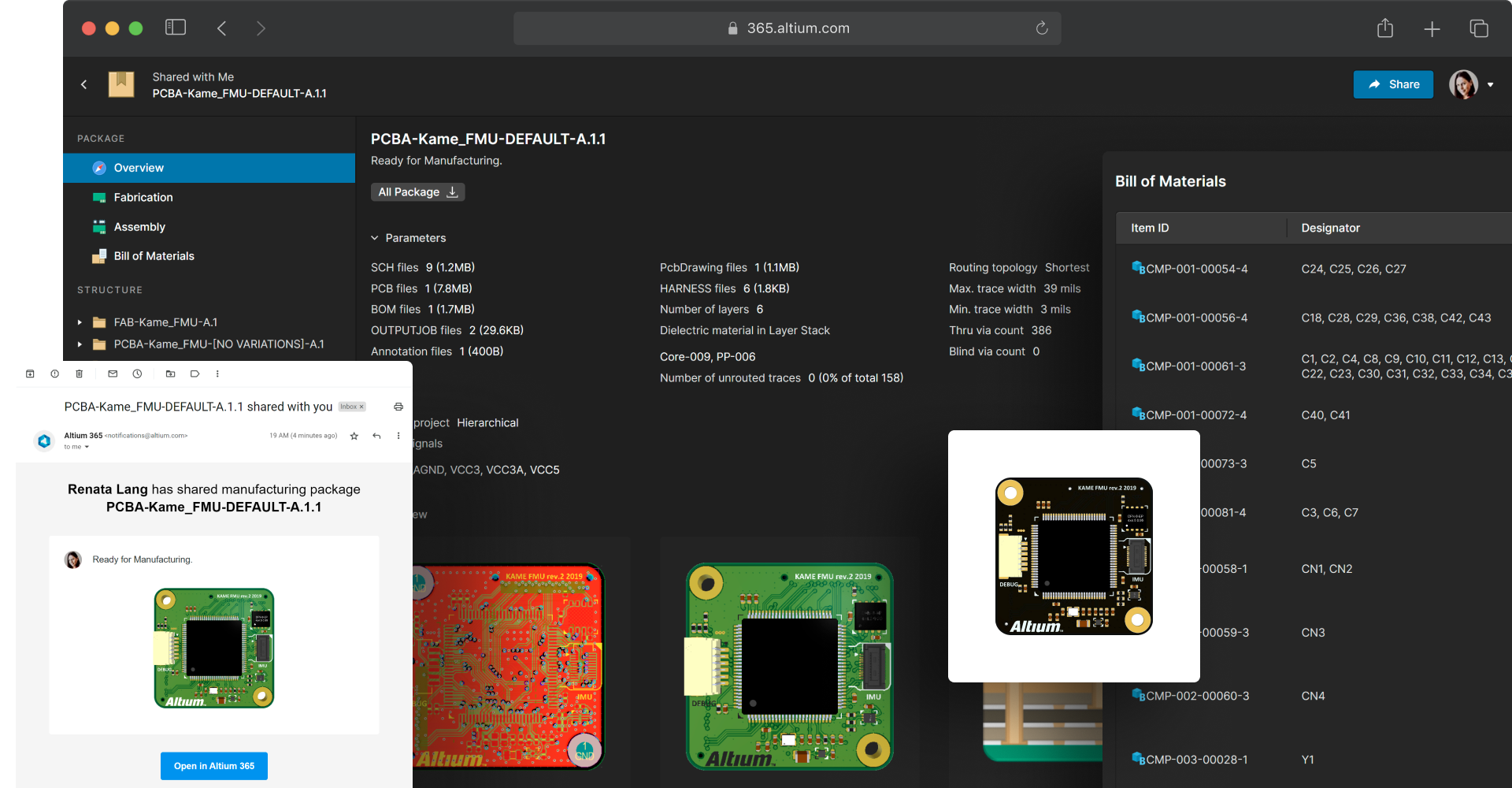

Collaborate easily with PCB manufacturers

Give PCB manufacturers secure, browser-based access to design files. Manufacturers can provide real-time feedback directly within the platform. Comments are attached to the design so issues can be addressed quickly in collaboration with engineers. Altium 365 reduces the risk of delays and respins while improving efficiency and accountability in industrial electronics manufacturing.

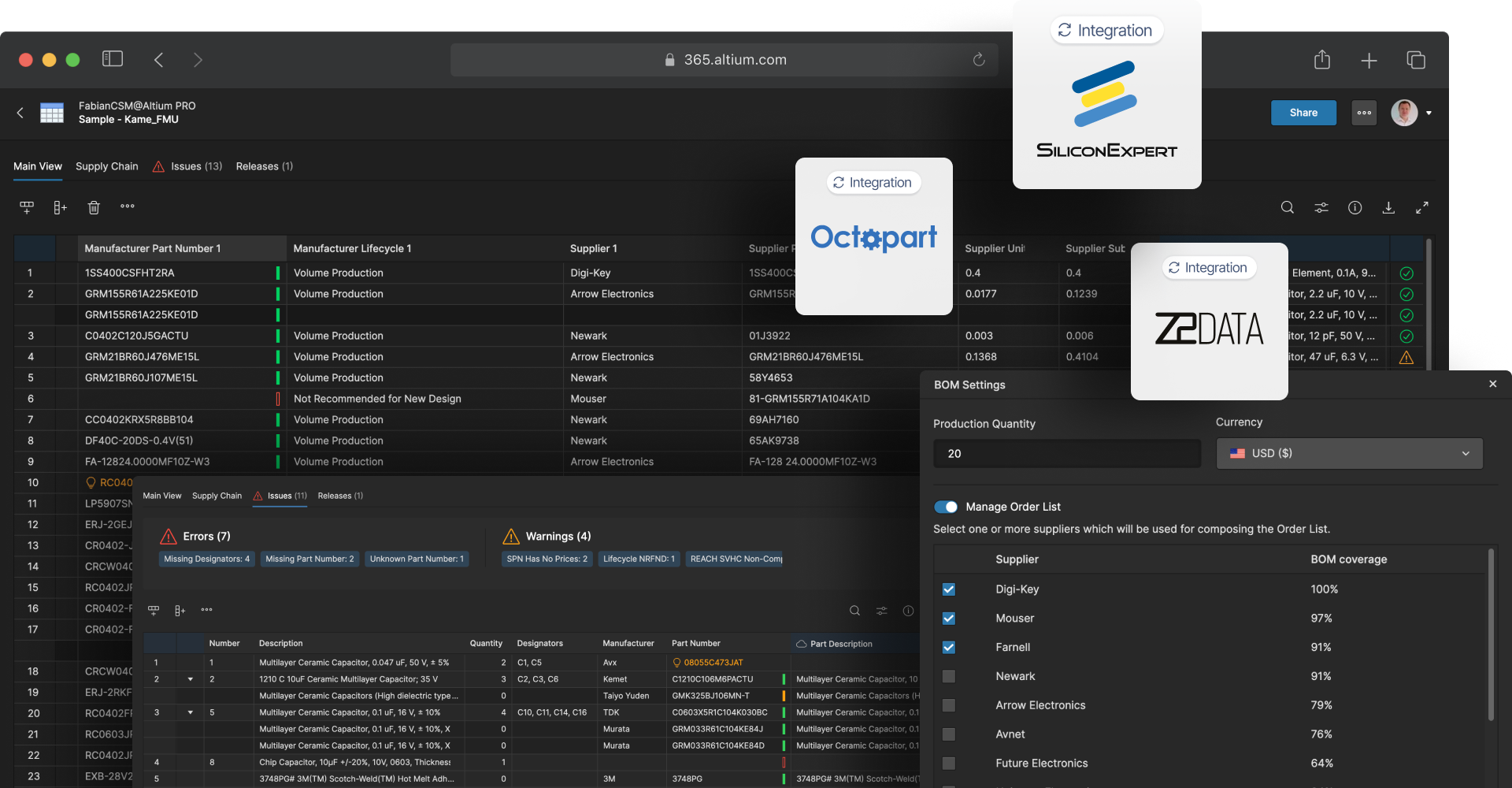

Optimize component sourcing with real-time data

Gain actionable supply chain intelligence with integrated access to real-time component data from Octopart, SiliconExpert, and Z2Data. Stay informed about availability, pricing, and lifecycle status to avoid sourcing obsolete or short-supply components. Industrial equipment manufacturers can make smarter component sourcing decisions to ensure projects remain on schedule and within budget.

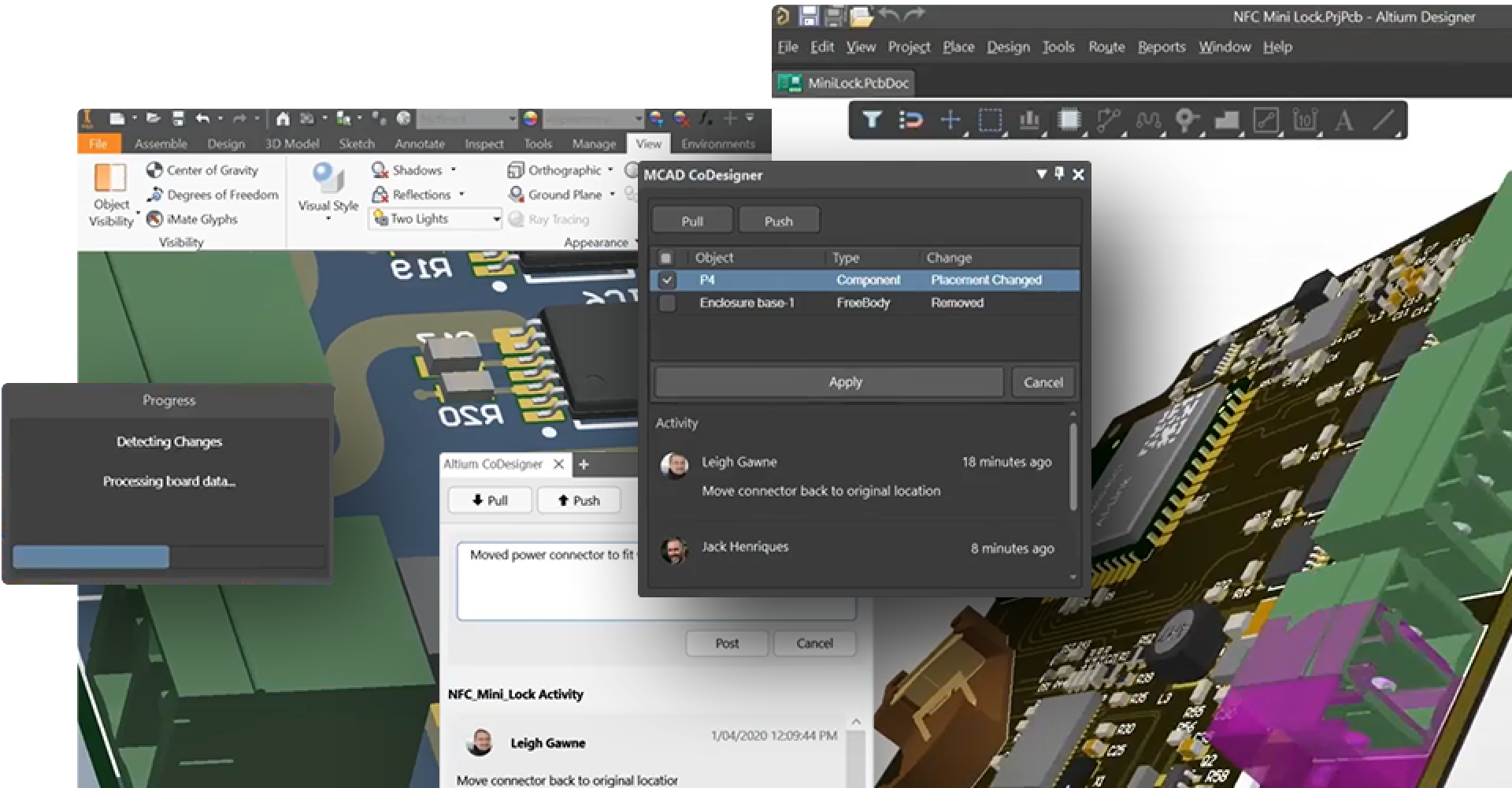

Align electronic and mechanical design teams

Bridge the gap between your industrial PCB design and mechanical design teams with ECAD-MCAD co-design. Two-way data exchange keeps teams aligned and reduces the risk of design conflicts and errors. The Altium 365 MCAD CoDesigner application supports the real-time transfer of ECAD data to MCAD systems to reduce iteration time and ensure that all requirements are met before industrial electronics designs are sent to manufacturing.

Trace requirements across the development lifecycle

Link functional and compliance requirements directly to design data for comprehensive requirements traceability. Verify and track requirements while automatically generating an audit trail that captures every decision and change. Altium 365 Requirements & Systems Portal improves accountability, enhances team alignment, and streamlines preparation for audits and compliance checks.

Secure industrial electronics IP

Protect industrial electronics design data and assets with industry-leading digital security. From secure data transmission and encrypted storage to fine-grained access control and user management, Altium 365 supports feature-rich collaboration while ensuring all aspects of your intellectual property stay safe. Regular security reviews and updates provide ongoing defense against espionage and cyber threats.

Resources

Blog

3 Common Challenges Stopping Your Production Line

Overcome time management, quality control, and risk mitigation challenges in hardware product development.

Blog

Accelerate Last-Minute Design Changes

Mitigate electronic development disruption with a unified digital architecture that supports collaborative issue resolution.

Blog

Why You Should Prioritize Cloud Data Security

Explore how cloud-based security strategies can provide robust, cost-effective, and flexible protection for your most sensitive electronic design data.

Frequently Asked Questions

Mistakes and miscommunications are common when teams work in siloes with incompatible tools. They often lead to misinterpreted design intent, incorrect component selection, and unresolved production constraints.

Altium 365 reduces errors in industrial electronics manufacturing by providing real-time collaboration and feedback between design and manufacturing teams. Manufacturers can review and comment on design files directly within Altium 365. All feedback is linked to the design files and visible to designers and engineers. This minimizes miscommunication and helps resolve issues before production begins.

Yes, Altium 365 enables two-way data exchange between ECAD and MCAD tools. Mechanical teams can view, collaborate, and provide input on designs using their preferred software, including SolidWorks, Siemens NX, and Autodesk Inventor.

Yes, Altium 365 integrates with PLM systems such as Arena and Duro. Integrations enable the synchronization of product data, including components, component parameters, and part choices, with product lifecycle management software. PLM integration ensures data consistency, reduces manual entry errors, and enhances collaboration across engineering and operations teams.

Altium 365 supports remote design reviews by allowing team members to access and comment on design files from any location via a web browser. Participants can view, annotate, and provide feedback directly on the designs, effectively collaborating remotely without the need to install software locally.

Altium 365 BOM Portal provides up-to-date information on component availability, pricing, and lifecycle status. Teams can quickly identify and replace obsolete or out-of-stock parts to avoid sourcing issues. Centralized BOM updates ensure that all stakeholders are working with the latest data, reducing errors and ensuring production schedules.

Ready to streamline

industrial electronics

development?

Get secure cloud collaboration purpose-built

for industrial equipment manufacturers.

- Improve design-to-manufacturing alignment

- Collaborate in a secure environment

- Enhance industrial electronics lifecycle management

- Reduce time-to-market for industrial equipment

Complete this form, and our electronics development experts will contact you soon.